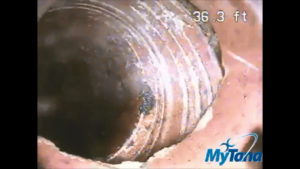

Last week in Brooklyn Harris Water was installing a new copper water main due to the existing lead water line leaking on the inside of the house. At the time of install the homeowner began asking questions about his sewer line after experiencing several backups over the previous week. We dispatched a camera crew to the site for a visual inspection on the inside of his sewer line.

The existing clay sewer line was in good condition until the point where it connected to the city sewer, which is also known as the “spur” connection.

Separation at spur connection |

What is a spur connection?

A spur connection is very similar to a wye in the city sewer and serves as the connection point for a new cast iron sewer line. Most cast iron sewer lines are 6” and will connect to a 6” spur, unless working in Manhattan which will require an 8” spur.

Harris was scheduled to begin working in the roadway for a spur repair as soon as the DEP permits were released. We began working two days later, after digging approximately 12’ deep in the roadway the crew reached the city sewer and began preparing new piping installation. This includes cleaning up existing soil around the spur connection with a shovel as well as the possibility of removing dirt with a backhoe.

Cleaning up around spur |

Removing soil with backhoe |

Now that the surrounding grounds were ready for piping to be installed with proper pitch, the 6” cast iron pipe was installed from the city sewer, to just before the curb line with 10’ of new pipe.

The first section of pipe installed |

Repair completed |

>

The repair was a standard one day repair and was ready for DEP inspection by 2pm the same day. Once the DEP inspection was completed Harris began back filling the roadway before leaving the roadway with steel plates.

Over the following days Harris follows DOT specifications for roadway restoration with our in-house paving team and had the entire job completed the same week.